创新的计量学,应用范围广泛:

- • 长度和直径

- • 表面和轮廓

- • 形状和位置

- • 齿轮和轴

液体和糊剂的精确混合与计量:

- • 齿轮计量泵

- • 纤维生产用泵

- • 计量混合分配机以及混合头

用于以下行业无间隙线性和旋转运动的转冲程轴承:

- • 机械工程

- • 精密工程

- • 光学

- • 电子

- • 以及许多其他行业

作为一家活跃于国际范围的公司,Mahr 不仅在德国拥有专利,在世界范围内也拥有专利。

Automation in Industry 4.0 - Minimize test costs

The measuring machines from Mahr can be networked with the production machines. Thus, in the case of deviating tolerances, the production can be adapted automatically. This safeguarding of the workpiece quality, which is free of operator errors, makes production significantly more reliable.

Networked machines in production

This vision relies on flexible, automated and networked machines in production. Mahr offers the right answers for quality assurance: Measuring camshafts on the MarShaft Scope 600 plus 3D shaft measuring system with workpiece loading by robot makes it possible, for example, to carry out measurements within the production line.

New possibilities in production systems

With the MarSurf CNC modular measuring system, Mahr also offers flexible and networked measuring of various workpieces: automatic parts recognition, part labeling and robot handling are new possibilities for measuring technology in today's and future production systems.

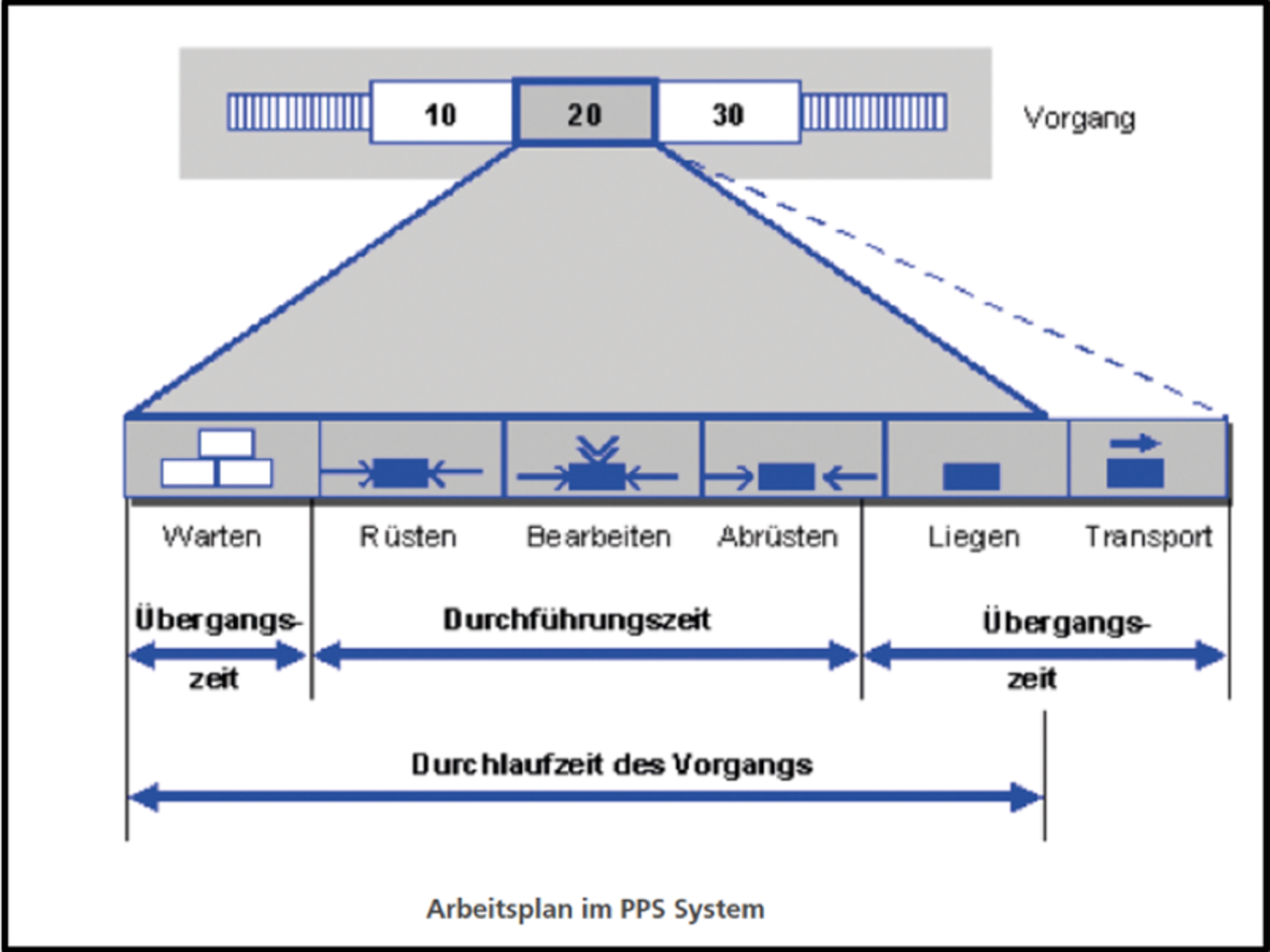

Integration of the measuring instrument into the organizational structure of the ERP system

A plurality of measuring programs are usually locally stored on a measuring machine which is, for example, used for five different workpieces. These programs are "mutations" and copies of the original programs and only the responsible worker knows exactly which one is the right measuring program for the machine. The more concise the measurement program, the more accurately the devices can measure. From this point of view, the integration of the measuring instrument into the organizational structure of the ERP system will be more important.

Integration in capacity management

In addition, integration in capacity management is taken into account so that at the end of the integration process only one measuring program is available on the measuring machine. This measurement program is then replaced by the new measuring program to be executed.