创新的计量学,应用范围广泛:

- • 长度和直径

- • 表面和轮廓

- • 形状和位置

- • 齿轮和轴

液体和糊剂的精确混合与计量:

- • 齿轮计量泵

- • 纤维生产用泵

- • 计量混合分配机以及混合头

用于以下行业无间隙线性和旋转运动的转冲程轴承:

- • 机械工程

- • 精密工程

- • 光学

- • 电子

- • 以及许多其他行业

作为一家活跃于国际范围的公司,Mahr 不仅在德国拥有专利,在世界范围内也拥有专利。

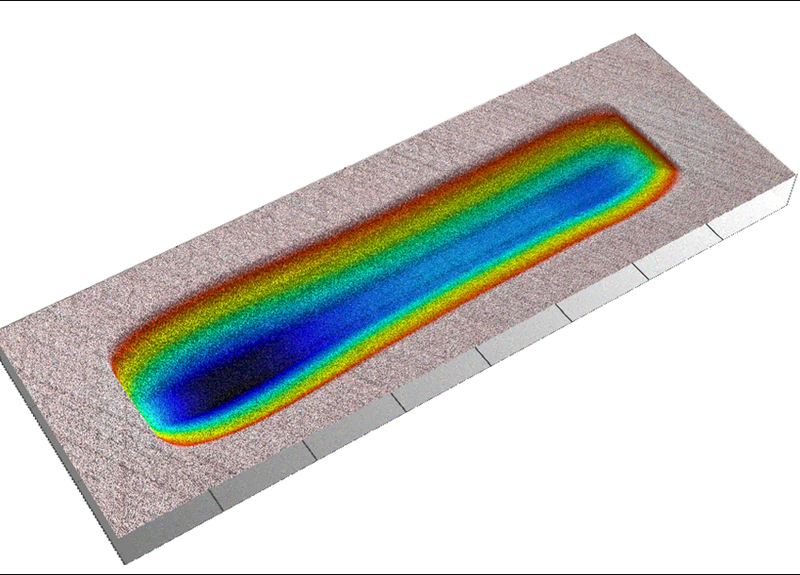

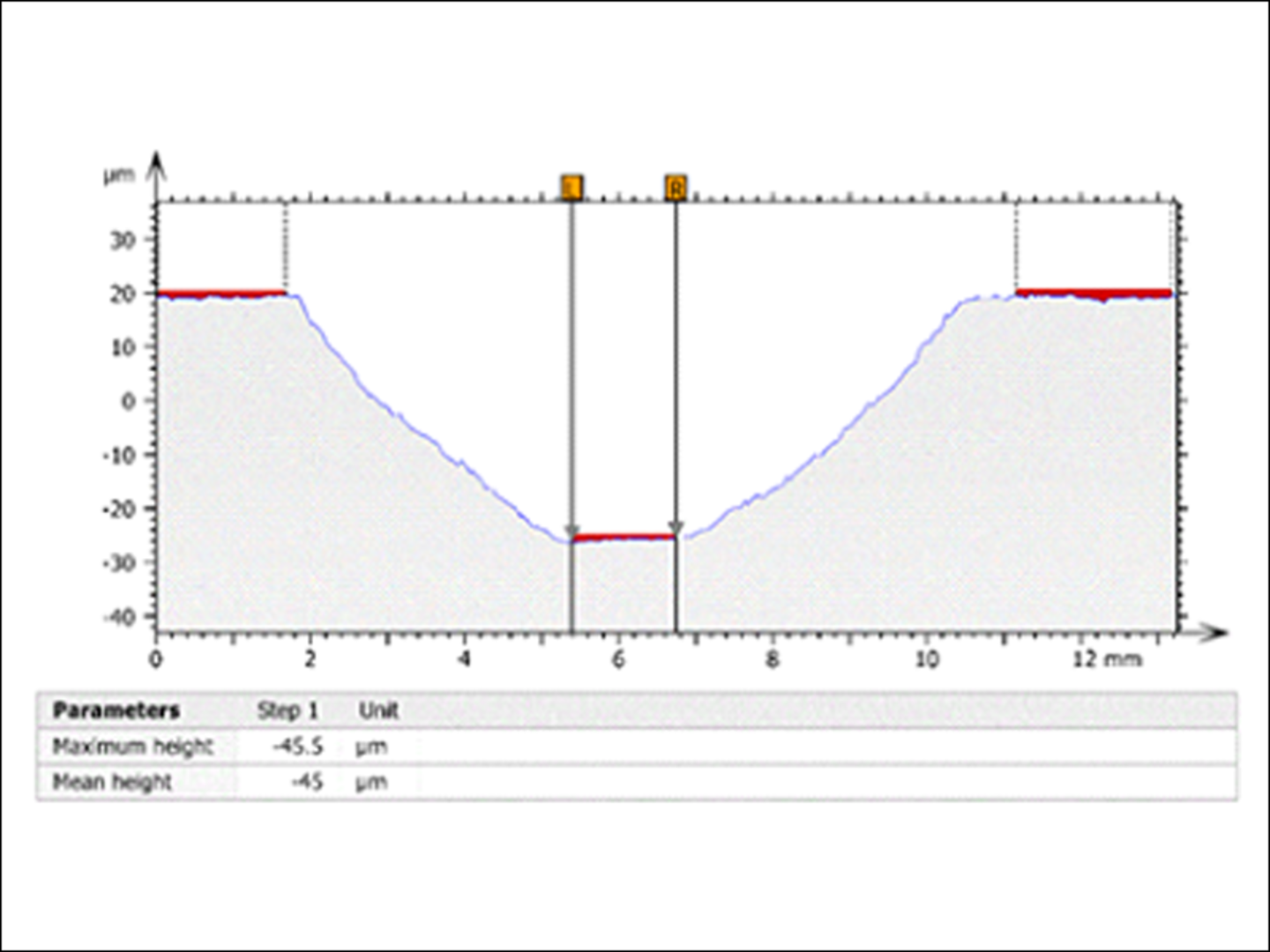

Quality assurance with optical 3D measurement: the tribo test

The wear test is carried out to check the service life of highly stressed materials such as ball bearings, piston rings or gear parts. Signs of wear, for example, show in the properties of texture or deformation of the surface. The analysis of the interaction of the material pairings is therefore essential for a later low-friction process.

Check with the tribo test

The areal data acquisition determines the maximum depth, the removed volume and the displacement of material. When determining the relevant characteristics such as roughness, the tribological properties or the surface quality, the high-resolution 3D analysis of the surface plays a central role. The results expose any product defects and determine whether a workpiece is ready for its intended use.

Capture 3D structural features: MarSurf CM explorer

That's why accurate, reliable records are indispensable. With the MarSurf CM explorer, all tribologically relevant 3D structural features are recorded, with which comprehensive analyses and evaluations are possible. Compared to scanning electron microscopy (SEM), the MarSurf explorer also provides absolute 3D measurement values.

At a glance:

- 3D images in true color with advanced analysis capabilities

- Non-contact measuring point detection

- Structural dimensions measurable from centimeter to nanometer

- Highest accuracy and repeatability of the measurement results

- Ultrafast measuring speed

- Standard compliant parameters

- Automatable measuring and evaluation processes

- Specified according to "Fair Datasheet“