创新的计量学,应用范围广泛:

- • 长度和直径

- • 表面和轮廓

- • 形状和位置

- • 齿轮和轴

液体和糊剂的精确混合与计量:

- • 齿轮计量泵

- • 纤维生产用泵

- • 计量混合分配机以及混合头

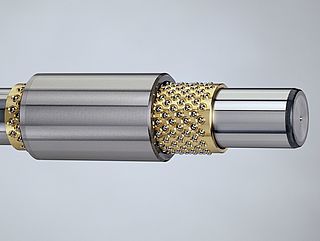

用于以下行业无间隙线性和旋转运动的转冲程轴承:

- • 机械工程

- • 精密工程

- • 光学

- • 电子

- • 以及许多其他行业

作为一家活跃于国际范围的公司,Mahr 不仅在德国拥有专利,在世界范围内也拥有专利。

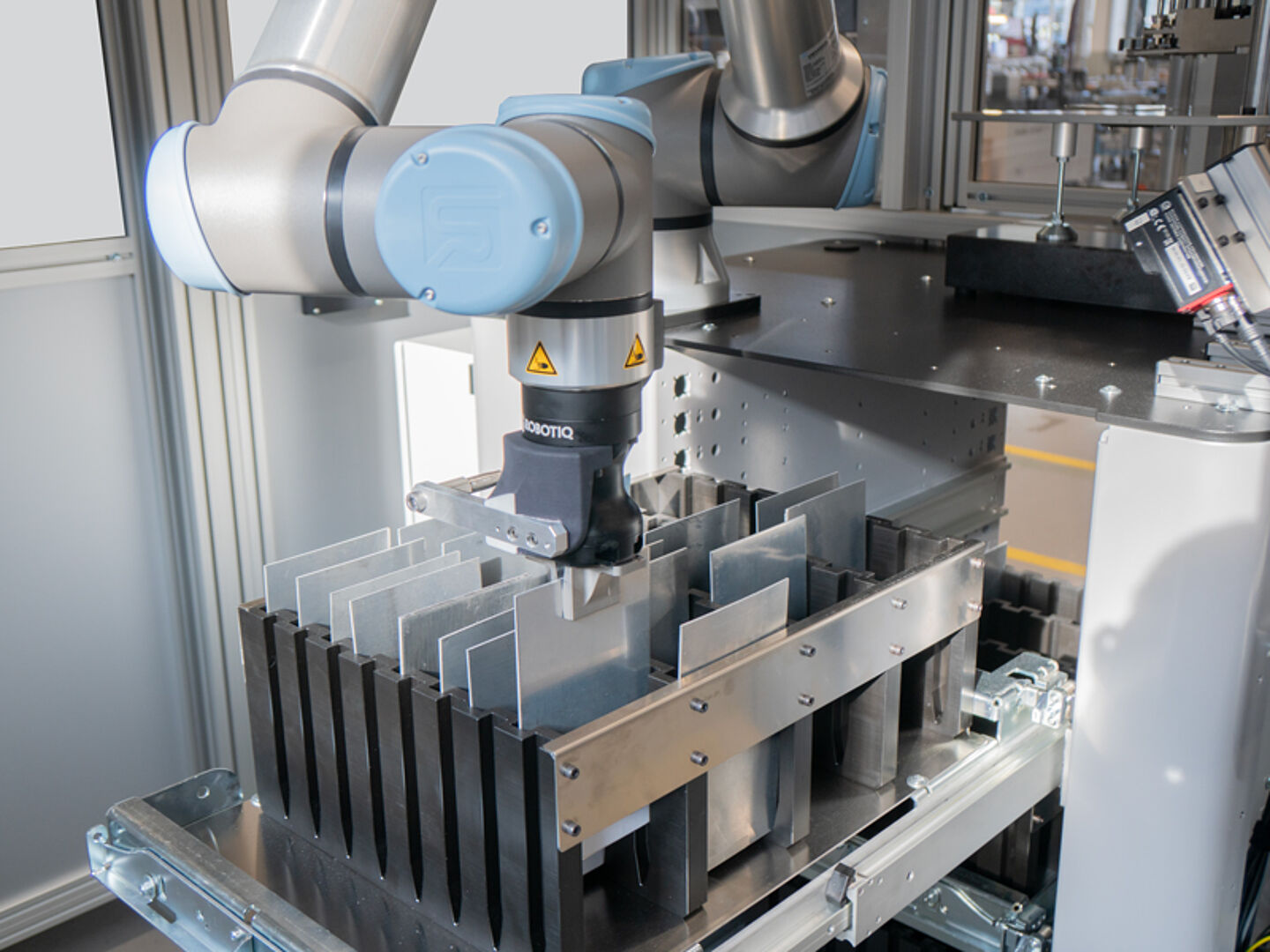

Automation solution for aluminum sheets

The two main components of the MES measuring station are, firstly, four MarSurf M 310 roughness measuring devices, which are actually mobile and combined in a special design as a stationary unit. They each have a double-skidded probe system. This means they meet the roughness standard applicable to sheet metal in accordance with DIN EN 10049:2014-03 and can measure the required roughness of Ra 0.25 µm.

Secondly, the measuring station is equipped with a collaborative robot including workpiece storage, the so-called Mahr Feeder. This automatically removes the sheet metal samples from the magazine, scans the applied QR code for identification and documentation and positions them in the measuring device. The samples are then measured from both sides and either approved or rejected depending on the result.

The advantages of this solution for the customer are manifold:

- By measuring only a very small sample, the customer can make a reliable quality statement for the entire coil.

- No personnel is required for measuring. An operator is only required to reload the samples into the workpiece storage.

- The service life of the measuring station is increased and even three-shift operation is possible.

- Overall, this increases throughput while reducing costs.

Further information on this topic can be found here:

- Would you like to realize your own project realize your own project with us? Find out more on our website.

- Click here for the product portfolio of Mahr Engineered Solutions.

- You can watch a video about the Mahr Feeder here.