创新的计量学,应用范围广泛:

- • 长度和直径

- • 表面和轮廓

- • 形状和位置

- • 齿轮和轴

液体和糊剂的精确混合与计量:

- • 齿轮计量泵

- • 纤维生产用泵

- • 计量混合分配机以及混合头

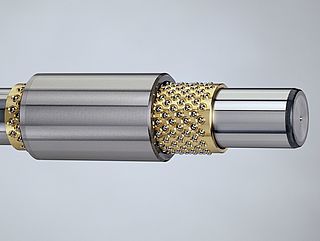

用于以下行业无间隙线性和旋转运动的转冲程轴承:

- • 机械工程

- • 精密工程

- • 光学

- • 电子

- • 以及许多其他行业

作为一家活跃于国际范围的公司,Mahr 不仅在德国拥有专利,在世界范围内也拥有专利。

Digitization & Automation at the EMO 2019

Trend topic: smart technologies

The EMO’s motto alone sets the focus of the trade fair: Smart Technologies DrivingTomorrow's Production. Mahr is also positioning itself with modern and smart product solutions: the digital wireless measuring devices, for example, have no annoying cable and thus maximize user friendliness during measurement. The new Precimar ICM 100 IP for automated dial gage testing also saves the user the need to manually read the pointer position for measuring instruments to be tested – and thus up to 60% time.

Robot-based, fully automated measuring cell at KUKA

Automation specialist KUKA, Mahr's cooperation partner, also presented the jointly developed robot-based measuring solution using the MarShaft Scope 750 plus Robot Ready. The special feature of the measuring machine is that it is automatically loaded by a robot, thus forming a fully automatic, optical shaft measuring system. It is to be used directly next to the production machine and inspect accompanying workpieces such as shafts and turned parts. Measuring machine, robots and production machines communicate via data interfaces such as OPC UA, fieldbus or QS-Stat and thus exchange data in closed-loop mode in order to guarantee the quality of the produced components in real time.

Comparable, easier, faster

The trend is clear: there continues to be a need for smart and automated products that both facilitate and improve work. This was also demonstrated by the many interesting discussions we had with you at this year's EMO. We say thank you for a successful trade show!

Impressions from the EMO 2019: