创新的计量学,应用范围广泛:

- • 长度和直径

- • 表面和轮廓

- • 形状和位置

- • 齿轮和轴

液体和糊剂的精确混合与计量:

- • 齿轮计量泵

- • 纤维生产用泵

- • 计量混合分配机以及混合头

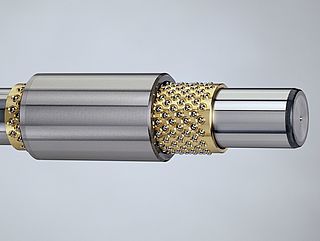

用于以下行业无间隙线性和旋转运动的转冲程轴承:

- • 机械工程

- • 精密工程

- • 光学

- • 电子

- • 以及许多其他行业

作为一家活跃于国际范围的公司,Mahr 不仅在德国拥有专利,在世界范围内也拥有专利。

MarSurf Engineered: Roughness measurement on gear teeth

This results in better power transmission and smoother running of the transmission. This in turn optimizes efficiency and reduces the running noise of the entire power train. While this relationship already applied to transmissions for conventional engines, it is becoming even more important in the age of the e-drive. In this context, the surface roughness on the gearing is an increasingly important parameter for optimizing transmissions.

High-precision roughness measurement with Mahr

Gears are ground in production down to a surface quality of Rz 0.2 µm. In order to be able to monitor this high requirement for surface quality in the production process in a stable and reliable manner, Mahr Engineered Solutions (MES) offers several suitable solutions for the necessary high-precision roughness measurement with the MarSurf portfolio, depending on the customer's requirements:

- Series 1300 for roughness measurement on smaller workpieces

- Series 2000 for roughness measurement on large workpieces

- 1400 Series combines roughness and contour measurement

- 503 Series offers individual solutions

Fully automated measuring stations thanks to MarSurf Engineered

Until now, roughness measurement at conventional roughness measuring stations was a tedious and complex task to ensure consistently high quality: Difficult accessibility on the gear down to the tooth root, extremely complex alignment of the teeth, and a high number of measuring points impaired correct measurement in line with standards. Therefore, a meaningful series monitoring was not possible. As a solution for this, Mahr Engineered Solutions offers fully automatic roughness measuring stations with its MarSurf series. These are specialized in high-precision roughness measurement and perform this easily and very quickly thanks to a very high degree of automation. Customers thus receive a measuring solution for their gear production that is precisely tailored to their needs – for more precision, speed and ultimately quality in value creation.

Interested?

If you are interested in a MarSurf measuring station, please contact us at info-engineered@mahr.com

- The solutions from Mahr MES for roughness measurement

- Our video on roughness measurement in gear cutting

- The product portfolio of Mahr Engineered Solutions

- You would like to realize your own project with us? Find more information here.